About Us

Our Story

Surface Resistance Technologies specializes in extending the service life of metals that can be damaged from erosion and/or corrosion. We have the expertise on staff that specializes with degradation of materials, welding and metallurgical engineering, and we utilize the best technology and applications to extend the service life of various metal components. Whether its tubular components used for oil and gas drilling, construction and excavation equipment or mining equipment, our specialty is to extend the life of components so that our clients can realize increased profits by reducing the need for replacement parts and minimizing downtime.

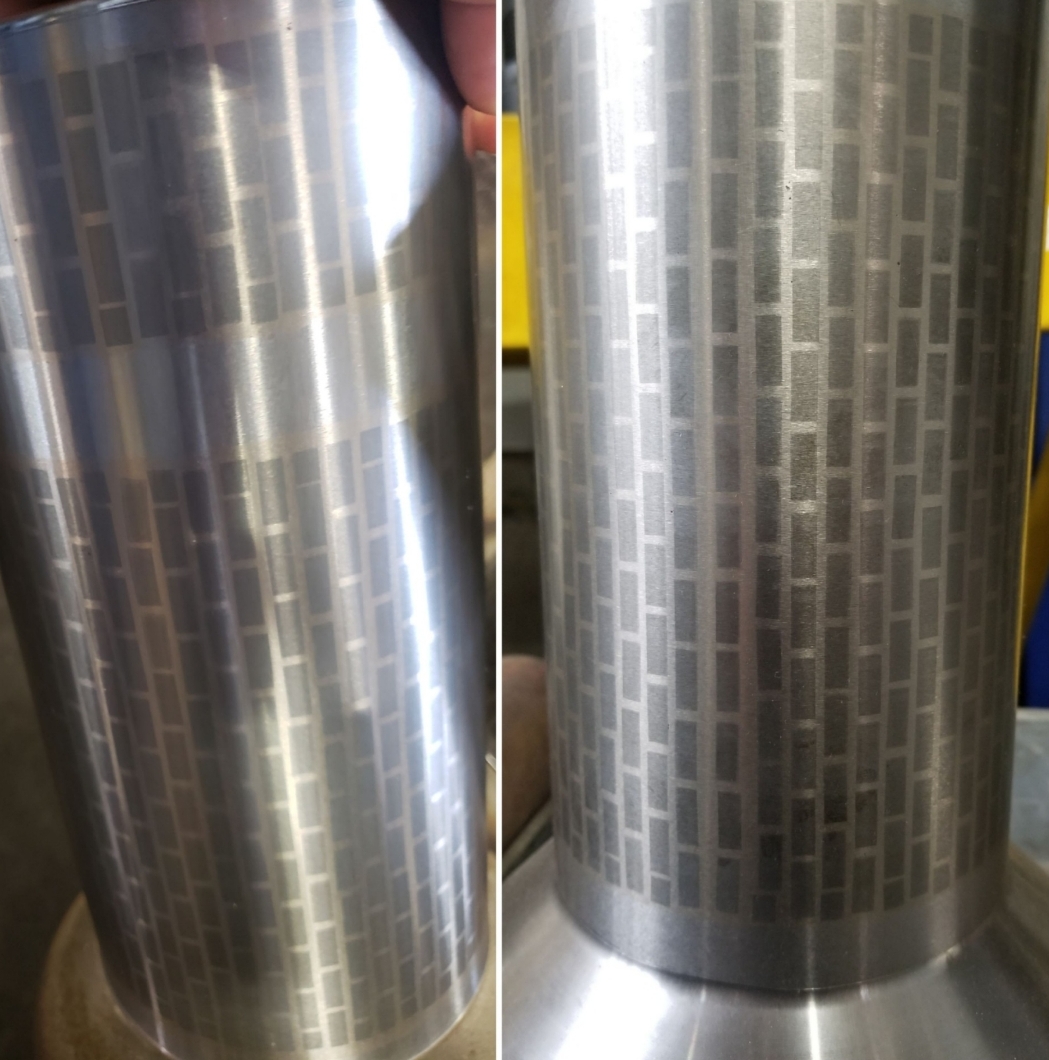

SRT not only provides service, we also have our own product line that consists of specially formulated metallurgical powders and wires specially designed for hard surfacing applications. We also have patent pending tungsten carbide tiles and inserts used for extreme wear resistant applications. SRT tile designs are proven to aide with achieving better fusion coverage of the entire tile, specifically in the very bottom of the tile where fusion is harder to achieve.

At SRT we put the extra effort in our objective to ensure that our products and services are “Above the Competition!”

Our Quality

We Have Experience

Our TEAM

We Provide the Best Service in Industry

At SRT, we specialize in the application of erosion/corrosion resistant materials to increase the life expectancy of equipment components and minimize downtime.